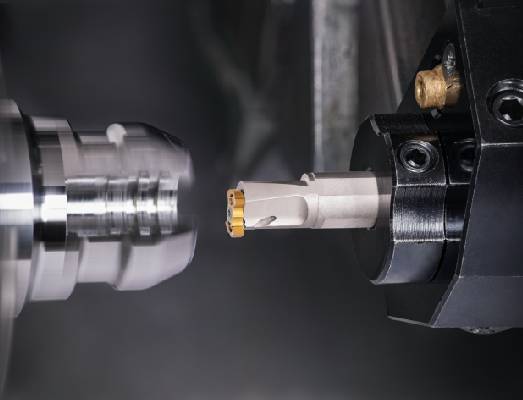

QUICK D MILL

Enables Using Each Four Cutting Edged Insert Twice for Guaranteed Exceptional and Efficient Machining

- Details

- Company Info

Details

BRAND : ISCAR

MODEL : LOGIQUICK

Enables Using Each Four Cutting Edged Insert Twice for Guaranteed Exceptional and Efficient Machining

1. Versatility Across Applications: The All-In-One line offers exceptional versatility, making it suitable for a wide range of milling operations. Whether you need to perform shoulder milling, hole making, or other milling tasks, the All-In-One cutters excel in various applications, eliminating the need for special tools and expand your machining capabilities.

2. Streamlined Operations: The combination of multiple functions in a single tool optimize machining processes and performs 50% of all milling applications. This streamlined approach reduces tool changes, setup time, and overall production costs, while enhancing operational efficiency and productivity.

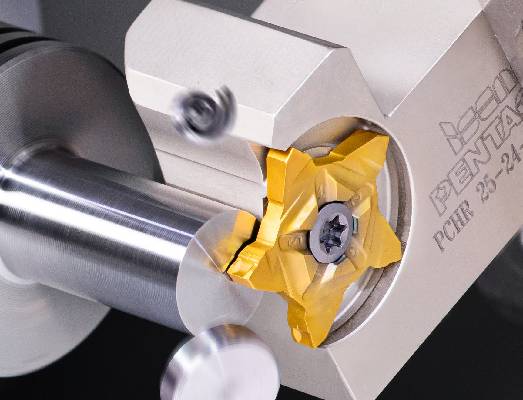

3. Unmatched Insert Economy: The unique design of All-In-One cutters allows each insert to be used for both center and peripheral edge cutting, which sums to four cutting edges. This innovative approach maximizes insert economy, reduces the frequency of insert replacements and lowers costs.

The new line includes

3 size inserts of 07,09,12 and PNTR chipformer coated with ISCAR’s SUMOTECH IC808/830/810 and the newest IC5600 multi-layer MT CVD coating and submicron substrate assures resistance to wear and improves productivity. Variety of tool range configurations:

1. Metric Endmill configurations of 16, 20 and 25mm for families of 07, 09 and 12 size inserts.

2. Inch Endmill configuration of 0.625”, 0.75” and 1.00” for families of 07, 09 and 12 size inserts.

3. A Multi-Master configuration features both metric and inch sizes of 16 (0.63”), 20 (0.79”) and 25 mm (0.98”) for families of 07, 09 and 12 size inserts with pinpointed High-Pressure coolant.

Tool and Insert Features

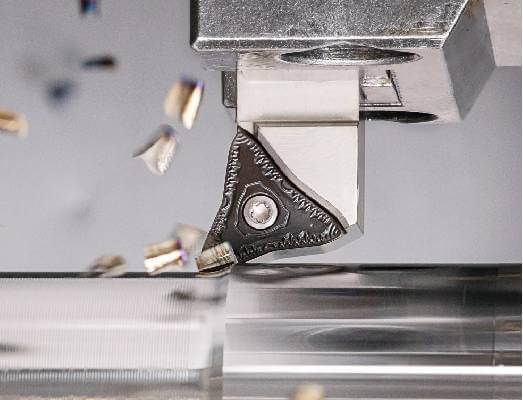

1. The new inserts are designed for right-hand machining and provide efficient and economical solutions for various 90° milling and drilling applications.

2. Available in three sizes of 07, 09, and 12. The inserts feature a PNTR positive land chipformer.

Primarily intended for milling ISO P materials such as carbon and alloy steel, , as well as ferritic and martensitic stainless steel Additionally, the inserts are suitable for milling ISO K materials such as gray, nodular, and malleable cast iron.

3. Each insert offers versatility with a total of 4 cutting edges (CE), assuring optimal insert economy. It comprises 2 cutting edges for center cutting and 2 peripheral cutting edges:

4. Each cutter has two flutes. One flute is intended for drilling operations with an effective number of flutes Zeff=1, and another is designed for milling operations with an effective number of flutes Zeff=2.

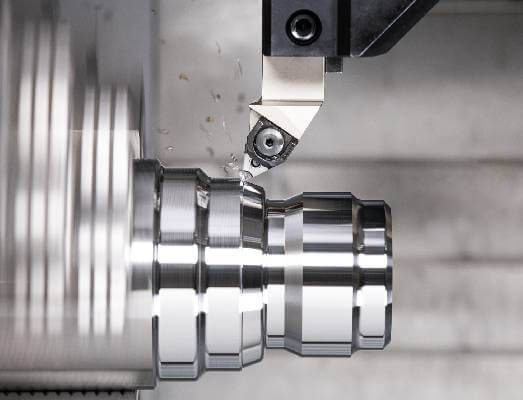

5. The insert pocket features a robust and durable design, incorporating a dovetail clamping mechanism for high process reliability. This precision engineering and cutting-edge design enhances stability during machining operations, minimizes vibrations and assures consistent performance for a smooth and high-quality surface finish.

6. The Multi-Master interchangeable heads offer a high-pressure coolant option, featuring pinpointed coolant flow directed to each cutting edge. This feature improves chip evacuation, reduces heat buildup, and prolongs tool life.

Applications

1. The new multi-function All-In-One line is attributed to a wide range of machining applications. The tools are appropriate for various tasks such as milling shoulders, slotting, complex contours, milling by use of ramping, drilling, contouring, plunging and more.

2. Flat Hole Bottoms: The new All-In-One cutters are designed to make hole bottoms as flat as possible. This feature assures precise flat surfaces at the bottom of the machined holes, meeting the requirements of applications that demand exceptional flatness.

Benefits

Enhanced Productivity

Streamlined processes, reduced tool changes and increased overall productivity

Streamlined processes, reduced tool changes and increased overall productivity

Cost Savings

Exceptional insert economy, reduced tooling costs and improved cost-effectiveness.

Exceptional insert economy, reduced tooling costs and improved cost-effectiveness.

Versatility

Excel in a wide range of applications and various materials, eliminating the need for multiple special tools, assuring versatility and adaptability to the different requirements of diverse industries.

Excel in a wide range of applications and various materials, eliminating the need for multiple special tools, assuring versatility and adaptability to the different requirements of diverse industries.

Extended Tool Life

Optimized tool life, reduced insert replacements and minimized downtime.

Optimized tool life, reduced insert replacements and minimized downtime.

Precision and Surface Finish

Ensure cuts with high machining precision and excellent surface finish.

Ensure cuts with high machining precision and excellent surface finish.

Time Efficiency

Simplified machining processes, saves time on tool changes and setup, for improved efficiency.

Simplified machining processes, saves time on tool changes and setup, for improved efficiency.

Reduced Inventory

Lowers tool inventory, reduced need for multiple specialized tools.User-friendly solution with foolproof insert clamping suitable for operators of different skill levels.

Lowers tool inventory, reduced need for multiple specialized tools.User-friendly solution with foolproof insert clamping suitable for operators of different skill levels.

Company Info

ISCAR (THAILAND) LTD.

บริษัท อีสคาร์ (ไทยแลนด์) จำกัด ให้บริการและจัดจำหน่ายเครื่องมือกลึง กัด ตัด เจาะ สำหรับงานโลหะแบบครบวงจรในอุตสาหกรรมยานยนต์, อุตสาหกรรมงานแม่พิมพ์, อุตสาหกรรมงานอิเล็คทรอนิกส์, อุตสาหกรรมการบินและอาก…

More Company Detail