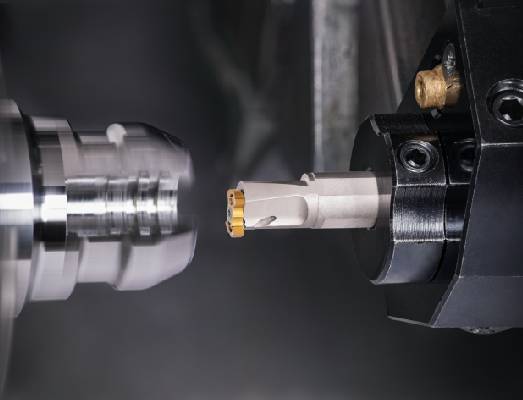

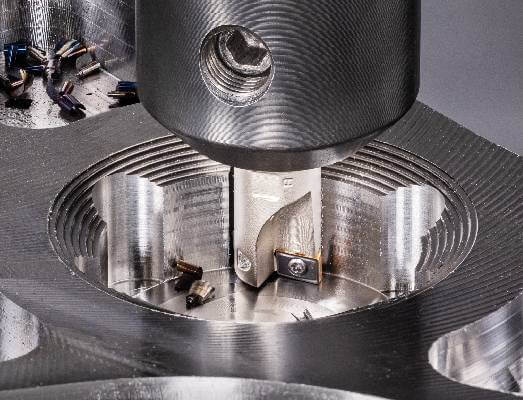

QUICK X FLUTE

- Details

- Company Info

BRAND: ISCAR

MODEL : LOGIQUICK

Cost-Effective Indexable Extended Flute Cutters for Achieving High Metal Removal Rates in Rough Milling Of Challenging Engineering Materials

1. Steel (ISO P group of application)

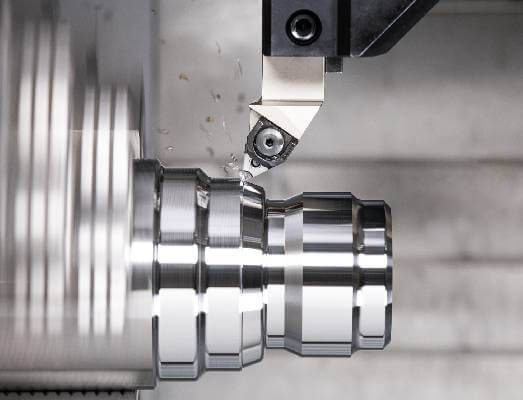

2. Stainless steel (ISO M)

3. High temperature superalloys and titanium (ISO S)

4. The new family of cutters provides manufacturers with a productive and cost-effective solution, ensuring high-quality machining parameters. These cutters enable significantly increased productivity and are primarily intended for milling hard-to-cut materials when producing high-value components, particularly critical-duty loaded parts in the Aerospace and Heavy Industries. The versatile cutting geometry of the new extended flute cutters (EFC) ensure efficient milling of a wide range of engineering materials.

5. The indexable inserts are made from various carbide grades to optimize machining for a specific material type.

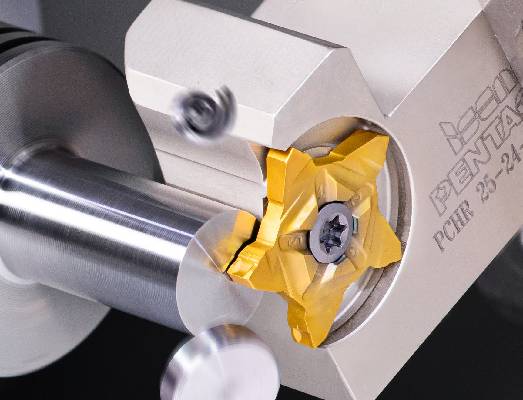

6. The EFC are available with one-body shell mill with a central bore design configurations.

7. The cutter is designed with an optimized flute geometry to improve the cutter’s dynamic behavior. The shape and volume of the flutes are determined to find a compromise between cutter rigidity and the necessity to provide effective chip flow when milling at high metal removal rate (MRR) with substantial radial engagement.

8. The new cutters feature an inner coolant supply option.

Insert Features

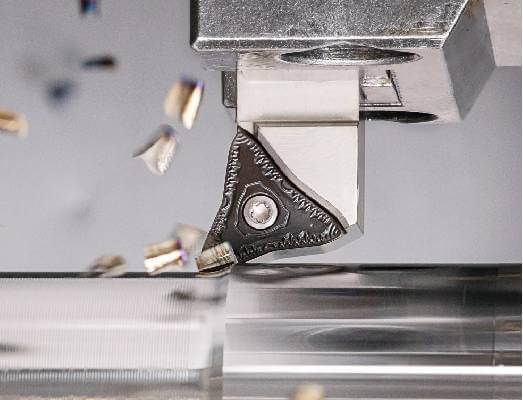

1. Double-sided square inserts with 8 indexable right-hand cutting edges.

2. The new inserts feature a High Positive (HP) chip-former with special edge preparation, ensure versatile cutting geometry for productive milling of steel, stainless steel, high temperature superalloys and titanium.

3. The new inserts are available in ISCAR’s advantageous MT CVD coated IC5820 and PVD coated IC830, IC840, and IC882 carbide grades, featuring a postcoating treatment. Additionally, there are inserts that are made from the latest PVD coated IC716 carbide grade, which has been developed specifically for high-performance machining titanium and titanium alloys.

4. The inserts are available with corner radii of 0.8 (.0315″), 3.2 (.126″) and 4 mm (.1575″)

Extended Flute Cutter Body’s Features

1. A unique flute geometry improves vibration resistance, especially during the entry and exit of the workpiece, providing better milling stability and enabling increased cutting data to enhance productivity.

Applications

1. The new indexable extended flute cutters (EFC) are optimized for rapid stock removal when roughing, especially when machining challenging high-strength steel, stainless steel, and aerospace materials like high-temperature superalloys and titanium.