SMART METALWORKING: Honor Seiki, Improve Vertical Lathe Machine with Tailor Made Solution!

Every factory has its advantages and weak points. That’s why the machine and solution requirements are also vastly different. With the new demand in the market that forces the factory to change at a fast pace, how can machinery respond to the need with flexibility especially in metalworking like lathe machines? These challenges also drive ‘Honor Seiki’ as a leader in total solutions in vertical lathe machines in Taiwan to support the manufacturer with innovation and tailor-made machines. Through the customers’ voices, Honor Seiki listened carefully and served them with the best solution for the business’s efficiency.

‘Lathe Machine’ The Changing Technology Under the Competitive Ages of Flexibility

Today, many manufacturers need to reduce processes in their production lines to minimize the cost, failure, and delay. The traditional lathe machine consumes more space than required, and that’s also one of the reasons for creating the new ‘vertical’ lathe machine. This change also drove together with new challenges, trends, and contexts of geopolitics which resulted in the development of vertical lathe machines in the form of CNC. CNC is more than just a lathe process which could reduce time and cost. As production becoming more complex, a vertical lathe machine must perform multiple tasks and must be able to connect with the factory system to evaluate every related parameter that responds to the customer need and the factory policies.

We must accept that the change in vertical lathe machines resulted from the fast-changing demand, for example, wind turbines or offshore energy that require highly durable parts and create more efficiency. The aerospace industry must adapt to use locally produced parts to respond to urgent maintenance and situations which is learned during COVID-19. These requirements reflected the need for modern technology with flexibility and reliability that suffice to respond to the need of the clouded future change.

As a leading company in vertical lathe machines, Honor Seiki gives priority to developing innovations to support the factory needs which cover all of the aspects without compromising reliability and improving quality at the same time.

Honor Seiki, Lathe Innovation Brewed from the Customer’s Voice

There is no better way to understand the famous Honor Seiki than to listen to Joseph Chen, general manager of Honor Seiki “We have experience in the vertical lathe machine for more than 35 years, that’s why we are one of the leaders in the industry. With our patents and experiences, we are famous in the international market for automation and innovation in lathe works including the design and integration of the system. We can respond to any requirement from customers and that’s why they recognize Honor Seiki as their trusted partner” Joseph told us about the whole picture of Honor Seiki with a kind smile that reflects how much he loves this business.

3 Driven Business Units for Honor Seiki in International Market

Joseph said that the history of the vertical lathe machine can date back more than 100 years. The traditional lathe machine has low productivity and can do only one task at a time. Today, the manufacturer needs more productivity and the machine needs to do more than one more task, needing a wider axis to reduce time and process. To respond to the challenges, Honor Seiki created 3 business units to support the manufacturer which are

- Standard/Customized Machine

- Industry Solutions

- Intelligent Integration

These 3 business units are working together to create the best value chain for the customer. With these units, Honor Seiki could customize the machine to fit the customer’s needs, for example, the vertical lathe machine from Honor Seiki has 30% more OEE when compared to traditional machines in the market for hard turning tasks. Through the combination of machine, solution, and integration, Honor Seiki could design a cyber-physical system, covering everything from the machinery, required applications, to digital systems.

‘The Voice of Customer’ A Key Message that Brings Honor Seiki Machine to the Factory Around the World

Why is Honor Seiki outstanding from the other brands? The truthful answer would be “They pay attention to the customer’s needs’. As we know, most of the major brands sell only the standard machine and they hardly make major changes for each customer. On the other hand, Honor Seiki does improvement and creates choices for customers, from standard machines to premium customized ones. If the customer has a special requirement to develop a new tool such as a special lathe tool, Honor Seiki can do it right away!

“We develop specialized equipment for customers with specific needs. In the past customer would need 2 machines to build a keyway, but 10 years ago we develop a machine to build a customized keyway with one machine, and that was the first in Taiwan. 5 years ago, a customer asked if our vertical lathe could make spline gears because their process took up to 9 hours to produce. So, we developed a special head that allowed our vertical lathe to produce spline gears. This innovation reduced the process to just 2 steps within our machine, cutting the time down to just 3 hours. We can reduce time to 1/3 of the traditional machine, which creates more productivity and reduces resource consumption” Joseph emphasized why Honor Seiki is a leading company in vertical lathe solutions. This capability also made Honor Seiki a trusted partner for the customer which means they can share their process of work to Honor Seiki to design and resolve the problem with efficiency starting from the design process, production, delivery machine, and integration.

Another case that shows how much Honor Seiki paid attention to detail was the time they invented the first vertical lathe wide-axis machine in Taiwan. The machine came with a fully premium function, but the price was high. Customers are interested in the machine‘s function and design, but the price is the main concern for them. Some of the customers thought that the machine was a bit over-spec because they needed a more economical one, so Honor Seiki developed the simple wide-axis machine for those customers. This is proof that Honor Seiki can respond to every customer’s need. Both an economical one or a newly developed function are possible for them.

Vertical Lathe Machine from Honor Seiki, Ignite the Innovation from Experiences and Customer’s Need

With the demand of manufacturing business increasing, the CNC machine needs to improve its precision to catch up with the requirements. This includes time reduction, less process, cost saving, and the smart function under the ecosystem of Industry 4.0. Honor Seiki responds to the trends through vertical lathe machine development based on the customer’s needs and their experiences as the leader in vertical lathe machines in Taiwan.

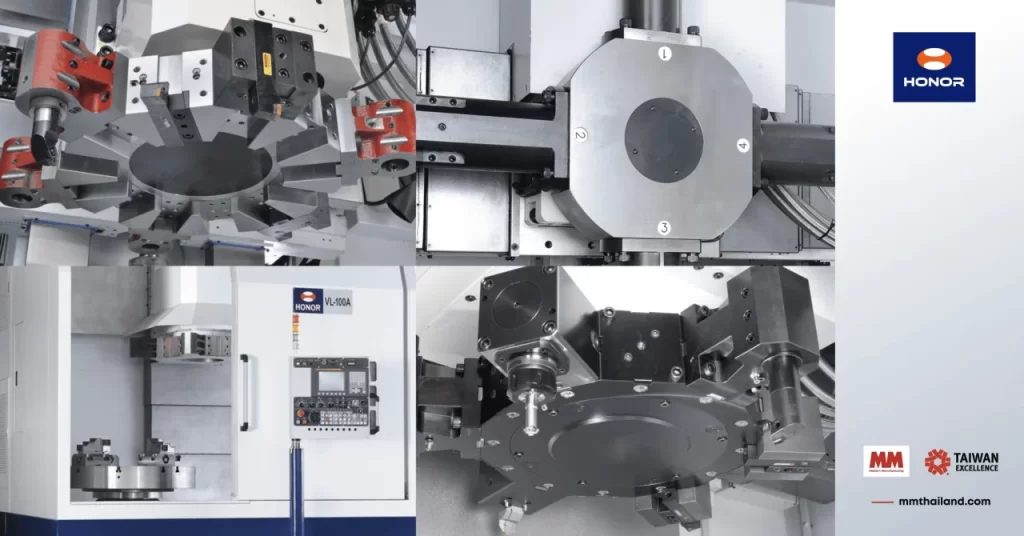

‘Solid Lock Tool Clamping System’ Honor Seiki’s Patent to Break the ‘Heavy’ Challenges in Vertical Lathe Tasks

In general, smaller lathe heads tend to have less rigidity. For the production of certain parts, such as gear milling, a customer will point out their requirement and Honor Seiki will take charge of designing and manufacturing the tool. With Honor Seiki’s unique patent ‘solid lock tool clamping system’, the machine’s clamping force could reach up to 10 tons and offers 70% more rigidity when compared to the other brands in the market. This might be the strongest one in the market too. This system lets the machine hold a bigger tool and is available for integration with various technologies.

‘Smart Machinery’ Starting from Hardware to the Digital Function

Modern manufacturing today needs high precision more and more especially in advanced industries like aerospace, electric vehicles, and wind turbines. These industries need superb quality, precision, and more efficiency. When the manufacturers use new materials, they will need a new method to adapt to different challenges.

Honor Seiki has developed its vertical lathes into smart machines that allow for online monitoring, reducing downtime, and enabling quick and convenient tool changes within the machine. For instance, they’ve added high-pressure coolant systems to solve the issue of hard-to-break chips, reduced calibration time, and integrated AI with EDGE computing to enhance and maintain production stability. These features create a faster response to the problem and allow engineers to work more efficiently and easily. When the machines becomes more intelligent, the business will operate more efficiently since recruiting skilled engineers is also a great challenge nowadays.

You can be confident that Honor Seiki’s vertical lathes come with innovations, solutions tailored to challenges, and value that meets manufacturers’ needs, regardless of the machine model or solution. Since there are many interesting solutions from Honor Seiki, we would like to introduce 2 outstanding machines.

VL-100CA: The Smart Vertical Lathe Machine for High Precision Industry

VL-100CA is a vertical lathe machine designed to address high-precision manufacturing challenges in the aerospace industry .

VL-100CA can reduce production time by 30% when compared to the older models. With the APC system, the operator can prepare the next workpiece from an external pallet while another piece is being machined inside the machine.. The machine is also equipped with a high-pressure coolant of up to 350 bar to resolve a hard-to-break chip material like titanium and extend the life of the tool at the same time. As the flagship machine, VL-100CA is also ready to use with a solid lock tool clamping system and all of the smart solutions such as energy management, machine monitoring, etc.

VL-160C Vertical Lathe for a Bigger Part

For the manufacturer who is looking for a machine to produce big workpieces , VL-160C is suitable for heavy-duty work with a wide axis and solid lock tool clamping system. This machine is worth the investment.

With high-grade Meehanite casting for dual vertical columns, the machine can reduce vibration greatly which gives VL-160C a great precision when working with heavy or hard turning parts. It supports a maximum weight of 8,000 kilograms and comes with 12 tool positions, making it perfect for industries requiring large, precise parts, such as aerospace and alternative energy wind turbine components.

Meets Honor Seiki and the Smart Vertical Lathe Solution at METALEX 2024

The manufacturers who are looking for smart vertical lathe machines can’t miss the opportunity to meet Honor Seiki at TAIWAN EXCELLENCE PAVILION in METALEX 2024.

For the manufacturers who are worried about the after-sales service from Honor Seiki, Joseph ensures that they have an engineering support team available in Thailand. Honor Seiki is ready to respond to calls of customers as fast as they can and there will be no Honor Seiki customer left behind without support.

“We will never leave the customer’s machine to face downtime. We need our vertical lathe machine to generate money for the customers all the time, since they paid for the machine. So they must get their money back and that’s our job”

– Joseph Chen, General Manager of Honor Seiki

Let’s meet with Honor Seiki and the other smart manufacturing solutions for metalworking from Taiwan at TAIWAN EXCELLENCE PAVILION in METALEX 2024, 20 – 23 November 2024 BITEC Bangna (Thailand). METALEX 2024 is free of charge to visit!

- Pages:

- 1

- 2