Smarter Human X Smarter Tech: Better Presses for Automotive Parts with ST1, Intelligent Power Presses With AI

The manufacturing industry of today faces a multitude of challenges, including labor and skills shortages, unpredictable demand fluctuations, and an increasingly volatile supply chain. To thrive in such circumstances, manufacturers must acquire essential qualifications. Among these qualifications, lean principles and flexibility have emerged as indispensable traits that every organization must embrace. Furthermore, automation, digitalization, and the rise of smart machines have become key drivers in overcoming the challenges of the modern manufacturing era.

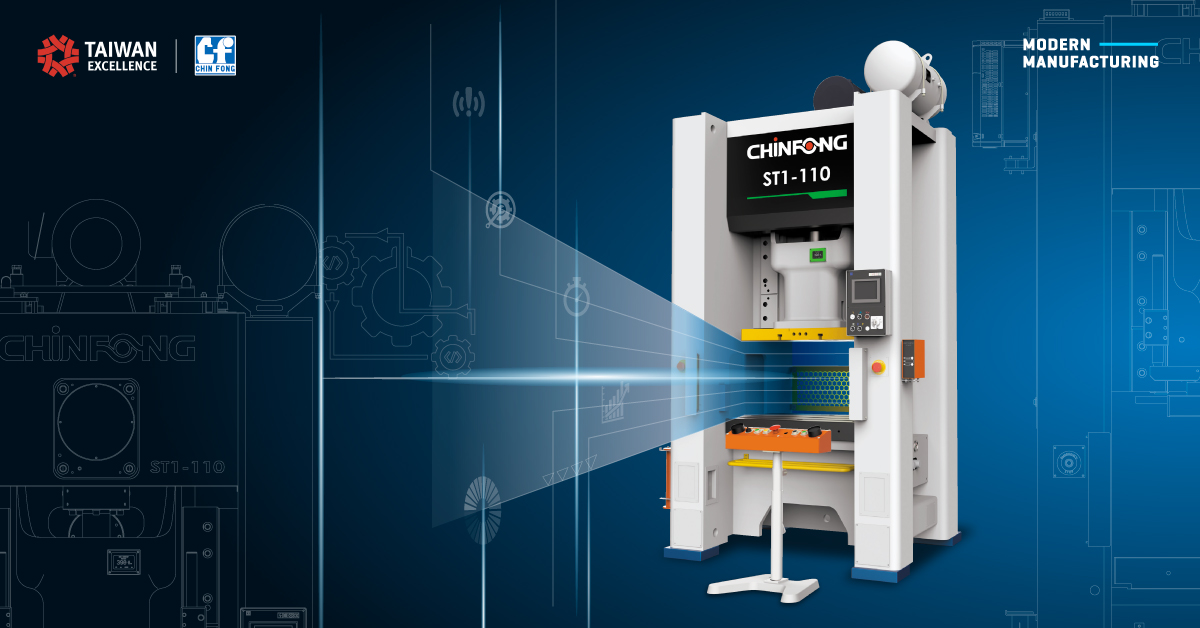

Recognizing the industry’s demand for smart machines that offer ease of use, high precision, and streamlined processes, Chin Fong Machine Industrial, a renowned manufacturer of press machines and a frequent recipient of the Taiwan Excellence Award, has developed the ‘ST1 Series’. The ST1 Series are straight side single crank precision presses equipped with AI smart features. This innovative solution is specifically designed to tackle the prevailing challenges in today’s manufacturing landscape and empower organizations to thrive in a rapidly evolving industry.

Embarking on the Journey Towards ‘Smart Machinery’: A Step for Factories to Take Right Now

When a manufacturer considers transforming, whether in their processes or business operations, it is crucial to take into account the costs associated with system upgrades, machinery investments, and the availability of skilled labor.

Many individuals associate factory automation with a significant investment in robotics or the elimination of human workers. However, the true essence of transformation lies in transparency and the optimization of internal resources. These two factors pave the way for lean principles and flexibility in manufacturing, enabling organizations to thrive in any situation. Smart machinery in a factory can respond to operational needs with enhanced efficiency, precision, speed, and quality. Such machinery serves as a vital catalyst for the next generation of manufacturing, particularly in press processing—a domain often overlooked by many.

Sara Hsieh, Overseas Sales Department Account Manager at Chin Fong Machine Industrial, emphasizes the necessity of smart machinery. “In an era of constant changes, the manufacturing sector faces numerous challenges. One global trend that has gained prominence is ESG (Environmental, Social, and Governance) compliance, which encompasses energy consumption, environmental impact, and carbon emissions. Despite this, business growth remains a key consideration in this equation. To address this trend, we have combined digital technology, data integration, and high-precision machine presses altogether.”

“We must acknowledge that cost and the availability of skilled labor are two primary barriers to transformation,” Sara adds. This understanding led Chin Fong to develop the value-centric ‘ST1 Series.’ Designed with small and medium-sized businesses in mind, the ST1 Series are user-friendly and easy for factory workers to comprehend. The earlier a transformation to smart machinery takes place, the better the outcomes are for businesses in terms of cost reduction, material optimization, time saving, and product quality improvement. With easy access to smart machines and without concerns about skill requirements, manufacturers can initiate their transformation journey confidently, seizing opportunities without hesitation.

‘ST1 Series’, Revolutionizing Metal Pressing With AI

Drawing on 70 years of expertise in machine press technology, Chin Fong understands the evolving requirements, needs, and trends within the manufacturing sector, particularly in metal pressing for the automotive industry.

Chin Fong’s machine press development is driven by a customer-centric approach, where they carefully consider the real-life applications and demands of their clients. Their technology continuously improves and adapts to meet industry needs, with a focus on high-precision presses that are user-friendly and compatible with the customer’s operating ecosystem, be it smart or otherwise. With this commitment in mind, Chin Fong has developed the Taiwan Excellence Award-winning ST1 Series to address the manufacturing landscape in the era of Industry 4.0.

ST1 Series: The Intelligent Power Press for Evaluation and Monitoring in Every Task

The ST1 Series are straight side single crank precision presses with the structural design optimized to ensure higher rigidity and reduced vibration during the pressing process. This design provides stability, precision, and extended machine life while minimizing noise. The ST1 Series are utilized in various pressing processes such as blanking extension, bending, engraving, flattening, cutting, and more, achieving a maximum production speed of 45 pieces per minute.

In addition to its rigidity and use of environmentally friendly materials, the ST1 Series offer three intelligent solutions. The first is the ‘iForming’ AI digital intelligent solution, which integrates with big data for real-time monitoring, machine management, predictive maintenance forecasts, and delivery time predictions.

The second intelligent solution is Automatic Mold Changing, an automation feature that significantly reduces setup and mold changeover time. Lastly, the ST1 Series incorporate PHM (Prognostics and Health Management) technology, which leverages data to calculate key maintenance aspects such as total clearance or predictive diagnostics, providing real-time insight into the machine’s condition. Operators can interact with the system through a user-friendly touch screen or remotely via network connectivity, enabling seamless integration into a smart factory environment.

In the context of Thailand’s prominent automotive industry and home appliances sector, the Intelligent Power Press ST1 Series can provide essential support, facilitating the production of high-quality parts and seamless integration with existing ecosystems. Manufacturers can achieve transparency and implement lean manufacturing principles through precise evaluation using the data generated by the ST1 Series, effectively overcoming the challenges prevalent in today’s manufacturing landscape.

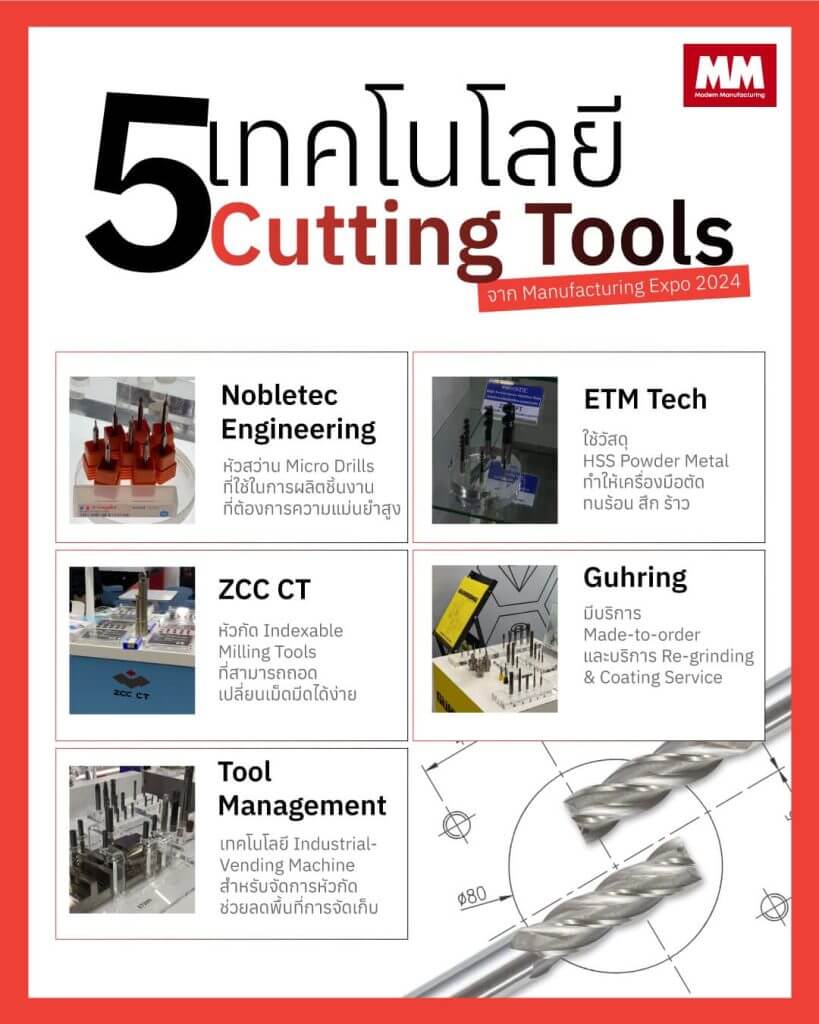

Chin Fong Machine Industrial is thrilled to announce its participation in the upcoming Manufacturing Expo 2023. The exhibition will take place at BITEC in Thailand from June 21 to June 24, 2023, between 10:00 AM and 6:00 PM.

At the event, Chin Fong will proudly present its flagship product, the ST1 Series. The state-of-the-art intelligent Power Presses are designed to significantly enhance manufacturing performance and efficiency. Attendees will have the unique opportunity to witness how the ST1 Series function through a 3D-printed model and to gain valuable insights into its cutting-edge features and advantages.

Do not miss this exceptional occasion to stay at the forefront of manufacturing innovation. Visit Chin Fong at the Taiwan Excellence Pavilion at Manufacturing Expo 2023 to experience firsthand the transformative capabilities of their intelligent Power Press.

About Taiwan Excellence

Taiwan Excellence believes that only innovation can bring about change for a better life. A cross-disciplinary team of jurors search and hand select innovative brands in Taiwan that are breaking the mold in sustainability, design, research, and development. The Taiwan Excellence mark has become one of the world’s most coveted and recognizable symbols of quality and design, showcasing Taiwan’s outstanding product innovation around the globe. Please visit https://www.taiwanexcellence.org/th/product for more information.

Taiwan Excellence “Empowering Smart Manufacturing” Product Launch @ Manufacturing Expo 2023 will start at 14:00 on June 21st in SILK 1 conference room. Click to register: https://forms.gle/QRg3kMRDSh7aBijG9

- Pages:

- 1

- 2